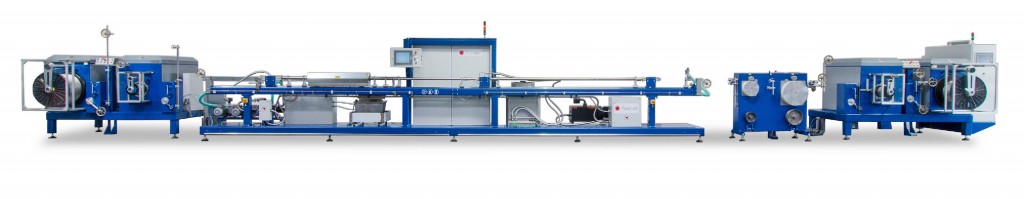

PlasmaANNEALER is a continuous heat treatment machine for ferrous and non-ferrous wire, rod, tube, and strip. Plasma heat treatment can be used for annealing, stress relieveing or hardening applications. Inert atmosphere in PlasmaANNEALER is selected to provide simultaneous surface treatment such as surface degreasing and oxide removal.

Watch a video of PlasmaANNEALER

Finished material benefits:

- Bright surface finish, scratch-free and without spark damage

- Simultaneous degreasing and deoxidation in inert atmosphere

- Adjustable mechanical properties

- Fine and uniform grain size

- Homogenous grain in transversal and longitudinal direction

- Less die wear in fewer wire breaks in subsequent drawing

Process features:

- High output annealing

- Lowest production costs in class

- Low energy, gas and maintenance costs

- Small production foot print

- Small power connection required

- No warming-up/cooling-down time

- Computer based controls with production and quality control features

Heat treatment: Annealing, stress relieving, hardening

Material form: Wire, rod, tube, strip, shaped wire, strand, rope

Process type: Continuous

Materials:

|

Download PlasmaANNEALER Product Sheet: